Stress Strain Graph For Brittle Material

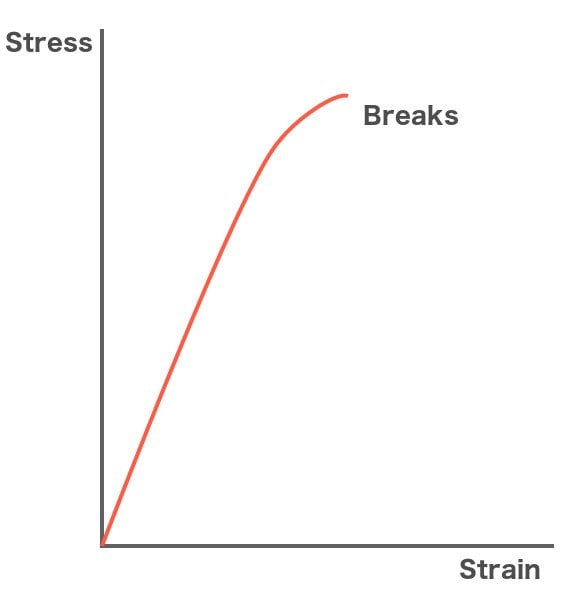

The stress-strain curve for brittle materials displays a linear relationship between stress and strain in the elastic region. Upon reaching the ultimate strength of the material, failure occurs almost immediately, with little or no plastic deformation before fracture. This behavior makes brittle materials more susceptible to damage under high.

Typical Stress Strain Curves for Brittle Materials Download Scientific Diagram

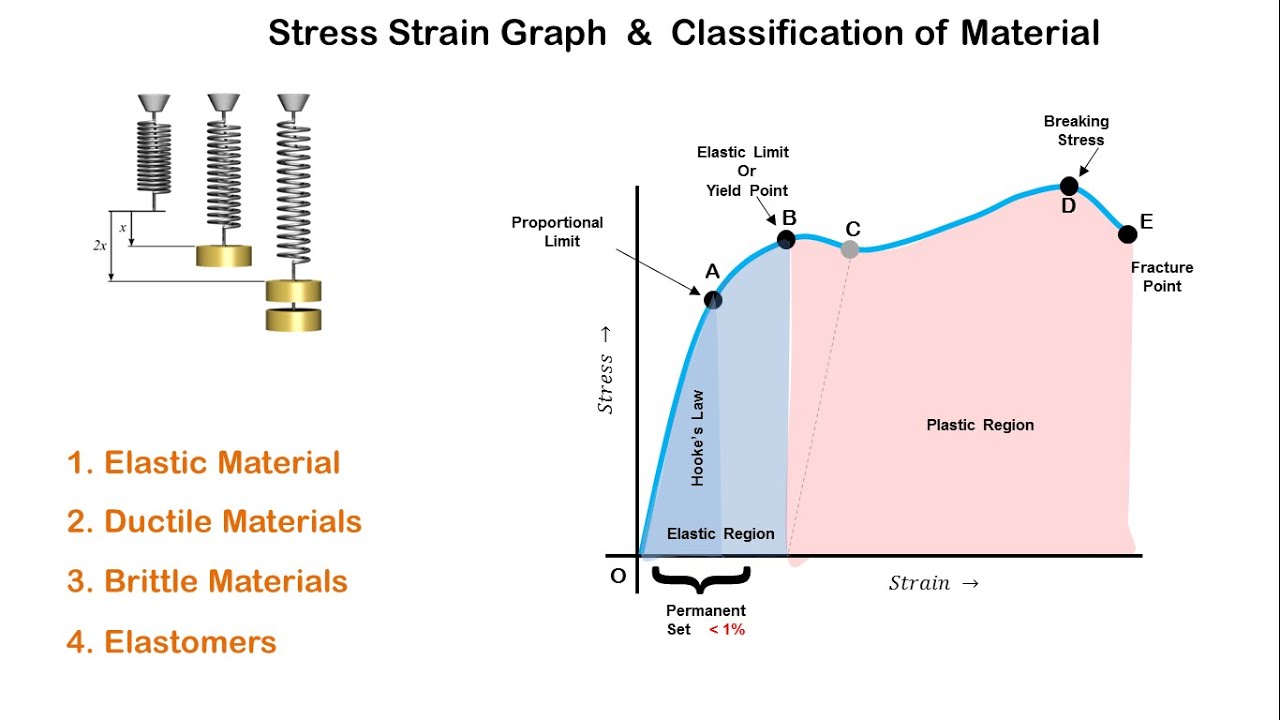

The stress-strain curve is the simplest way to describe the mechanical properties of the material. The stress-strain curve can provide information about a material's strength, toughness, stiffness, ductility, and more.. Ceramics tend to have much higher yield strengths, but because they are so brittle, their yield strength, ultimate.

(a) Stress/strain relationships for brittle, plastic, and elastomeric... Download Scientific

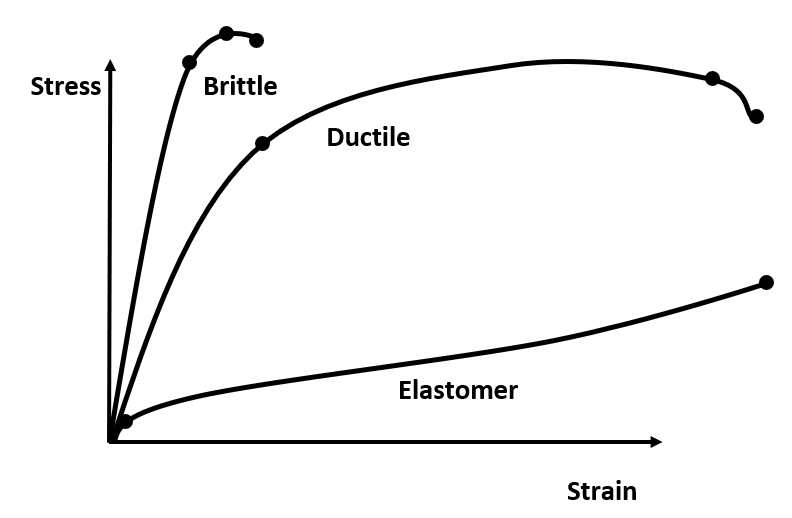

Stress-strain curve for brittle vs ductile material. There is no well-defined point that classifies brittleness, but typically a material that fractures at a strain of less than 5% is considered a brittle material. Understanding the ductility and brittleness of materials is crucial for designing and manufacturing safe and reliable products.

Typical stressstrain curves in brittle, brittleductile, and ductile... Download Scientific

The stress-strain curve of a brittle material is a steeply sloped line that shows the stress increasing rapidly with little strain. Unlike ductile materials, the stress-strain curve for a brittle material shows little plastic deformation after the yield stress (yield point) is reached. The material fractures soon after the yield stress.

Stressstrain curve (solid line) of a brittle material undergoing at... Download Scientific

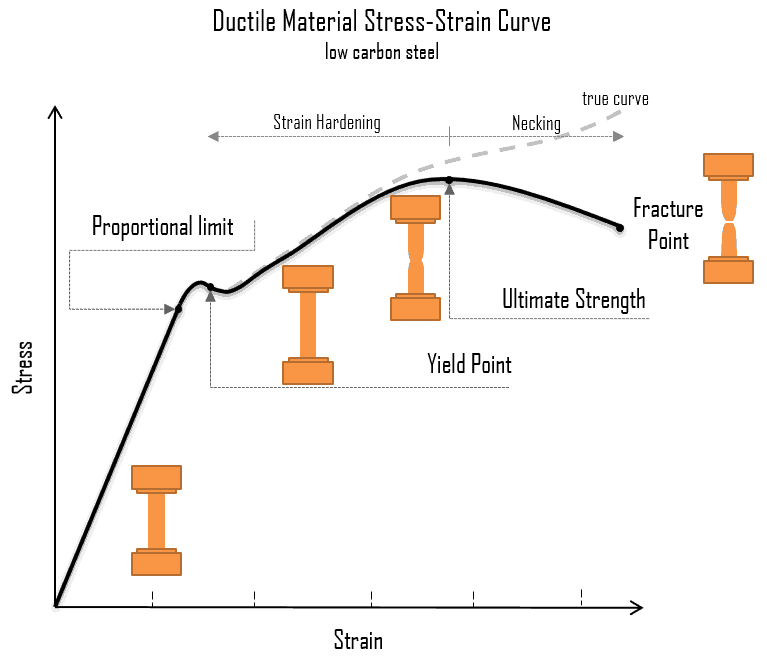

18.4 : Stress-Strain Diagram - Brittle Materials. Brittle materials, including glass, cast iron, and stone, exhibit unique characteristics. They fracture without considerable change in their elongation rate, indicating that their breaking and ultimate strength are equivalent. Such materials also show lower strain levels at the point of rupture.

Explain Stress Strain Curve For Brittle Material DFINITUS

The stress-strain curve is a fundamental mechanical representation that elucidates the behaviour of materials under applied load, offering insights into their deformation characteristics. This curve unveils a distinct mechanical response marked by minimal plastic deformation and a sudden, catastrophic failure in the context of brittle materials, such as ceramics, certain metals, and glass.

Brittleness Strength How to identify on stress strain curve YouTube

Stress-strain curve of a ductile material. This is also true for region AB, except that the material in this region doesn't obey Hooke's law, a fact one can easily discern from its non-linear shape.. Brittle Curve. Brittle materials such as glass share the same relationship except they don't exhibit a yielding phenomenon. These.

Explain with examples, ductile materials, brittle materials and elastomers on the basis of

18.4: Stress-Strain Diagram - Brittle Materials. Brittle materials, including glass, cast iron, and stone, exhibit unique characteristics. They fracture without considerable change in their elongation rate, indicating that their breaking and ultimate strength are equivalent. Such materials also show lower strain levels at the point of rupture.

STRESS STRAIN CURVE DUCTILE BRITTLE MILD STEEL CIVIL ENGINEERING YouTube

that block dislocation motion, are usually brittle rather than ductile. The stress-strain curve for brittle materials are typically linear over their full range of strain, eventually terminating in fracture without appreciable plastic flow. Note in Fig. 2 that the stress needed to increase the strain beyond the proportional limit

Idealised example of stress/strain curves. Curves for two different... Download Scientific Diagram

The formula for calculating material stress: σ=F/A, where. F is force (N) A is area (m 2) σ is stress (N/m 2 or Pa) For example, a force of 1 N applied on a cross-sectional area of 1 m 2, will be calculated as a stress of 1 N/m 2 or 1 Pa. The unit can be displayed as N/m2 or Pa, both of which represent pressure.

What is Concept of Stress and Strain Stressstrain Model Definition Material Properties

A brittle material is a material where the plastic region is small and the strength of the material is high. The following figure shows a typical stress-strain curve of a ductile material and a brittle material. A ductile material is a material, where the strength is small, and the plastic region is great. The material will bear more strain.

Stress Strain Graph and Classification of Materials YouTube

The brittle curve of Figure 1 coupled with unloading path 2 illustrates the typical stress-strain curve observed in pure shear failure on a set of experimental masonry shear walls (Nichols, 2000).

Stress, Strain, and the StressStrain Curve Materials Science & Engineering

Stress-strain curve for brittle materials compared to ductile materials. It is possible to distinguish some common characteristics among the stress-strain curves of various groups of materials and, on this basis, to divide materials into two broad categories; namely, the ductile materials and the brittle materials.: 51

Stress and Strain Relationships Explained saVRee

2. Sketch two Stress/Strain Curves on the same graph, making one Curve for a brittle material and one Curve for a ductile material. Below the graph, briefly mention in your own words what the key difference is between the two types of material. Steps to Analyzing a Material's Properties From Its Stress/Strain Curve: Intro: "How does this.

Stress strain curves for Brittle material and Ductile material

The stress-strain curve for brittle materials are typically linear over their full range of strain, eventually terminating in fracture without appreciable plastic flow. Note in Figure 2 that the stress needed to increase the strain beyond the proportional limit in a ductile material continues to rise beyond the proportional limit; the material.

Stress Strain curve for the ductile and brittle materials mechanical design YouTube

When a brittle material is subjected to increasing stress, the resulting stress-strain curve is characterized by a sudden and sharp decrease in stress upon reaching the maximum load carrying capacity, also known as the ultimate tensile strength. This drop in stress is due to the propagation of cracks, which quickly spread through the material.

- Cook Islands Weather By Month

- What Is Googly In Cricket

- 1 1 4 Sch 40 Pipe Dimensions

- Is There Fireworks On Australia Day In Perth 2024

- Obelisco Di Piazza San Pietro

- David Jones Sydney Elizabeth Street

- Full Face Mask And Snorkel

- Supernatural Season One Episode 1

- What Does Pps Stand For

- Houses For Sale Floreat Perth