Creative DIY Plastic Bottle Flower

In thisplastic bottle manufacturing process of extrusion blow moulding, a hot tube of plastic material (parison) is dropped from an extruder and captured in a water-cooled mould. Once the mould is closed, the air is injected through the top of the container. When the hot plastic blows up and the mould material freezes, allowing it to be able to.

Infographic How a Bottle Gets Recycled KIDS DISCOVER

It takes at least. 450 years. 450 years. for a plastic bottle to completely degrade. Engineer Nathaniel Wyeth patented polyethylene terephthalate (PET) bottles in 1973. The first plastic bottles.

20 Amazing Things To Make From Plastic Bottles

Known for its quality and environmental friendliness, PET plastic bottles and jars are made using a unique process called Stretch Blow Molding, or SBM. There are two SBM manufacturing techniques: Single Stage and Two Stage Process. Both are divided into three similar and distinct steps: Preform, Conditioning, and Blow & Stretch. What's really.

What Are the Raw Materials of Plastic Bottles? • Bernard Laboratories

The Bottle-Making Process. PET bottles are typically created using one of the three blow molding processes listed below. Injection Blow Moulding. Ideal for smaller plastic bottles, the Injection Blow Moulding process can be used to mould a wide variety of polymers including PET and HDPE.

How is Plastic Made? (with pictures)

Plastic bottle manufacturing takes place in stages. Plastic bottle manufacturers generally use one of four types of plastic to create bottles. Typically, the plastic bottles used to hold potable water and other drinks are made from polyethylene terephthalate (PET), because the material is both strong and light.

Plastic Bottle Manufacturing Process How Plastic Bottles are Made • Bernard Laboratories

In this manufacturing method for plastic bottles, the material is heated until it becomes workable, then extruded into a hollow tube, known as a parison. This parison then goes onto the next stage, where a cooled mold is used with hot pressurised air. Firstly, the mold clamps the parison into position.

Plastic Bottle Manufacturing Process How Plastic Bottles are Made? by SailorPlastics Issuu

Direct methods include using pressurized air or carbon dioxide directly on the mold and plastic. "Once the bottle (or, in continuous manufacturing, bottles) has cooled and set, it is ready to be removed from the mold. If a continuous molding process has been used, the bottles will need to be separated by trimming the plastic in between them.

Aluminum vs. Plastic Cost The Process of Plastic Production PATH Water

Like paper and glass, plastic is the product of a complex process. Plastics are polymers. A polymer is a large molecule made of smaller ones, called monomers. These monomers are derived from materials found in nature, such as natural gas, oil and plants. The bottom line is it takes a lot of labor and expertise to manufacture plastics.

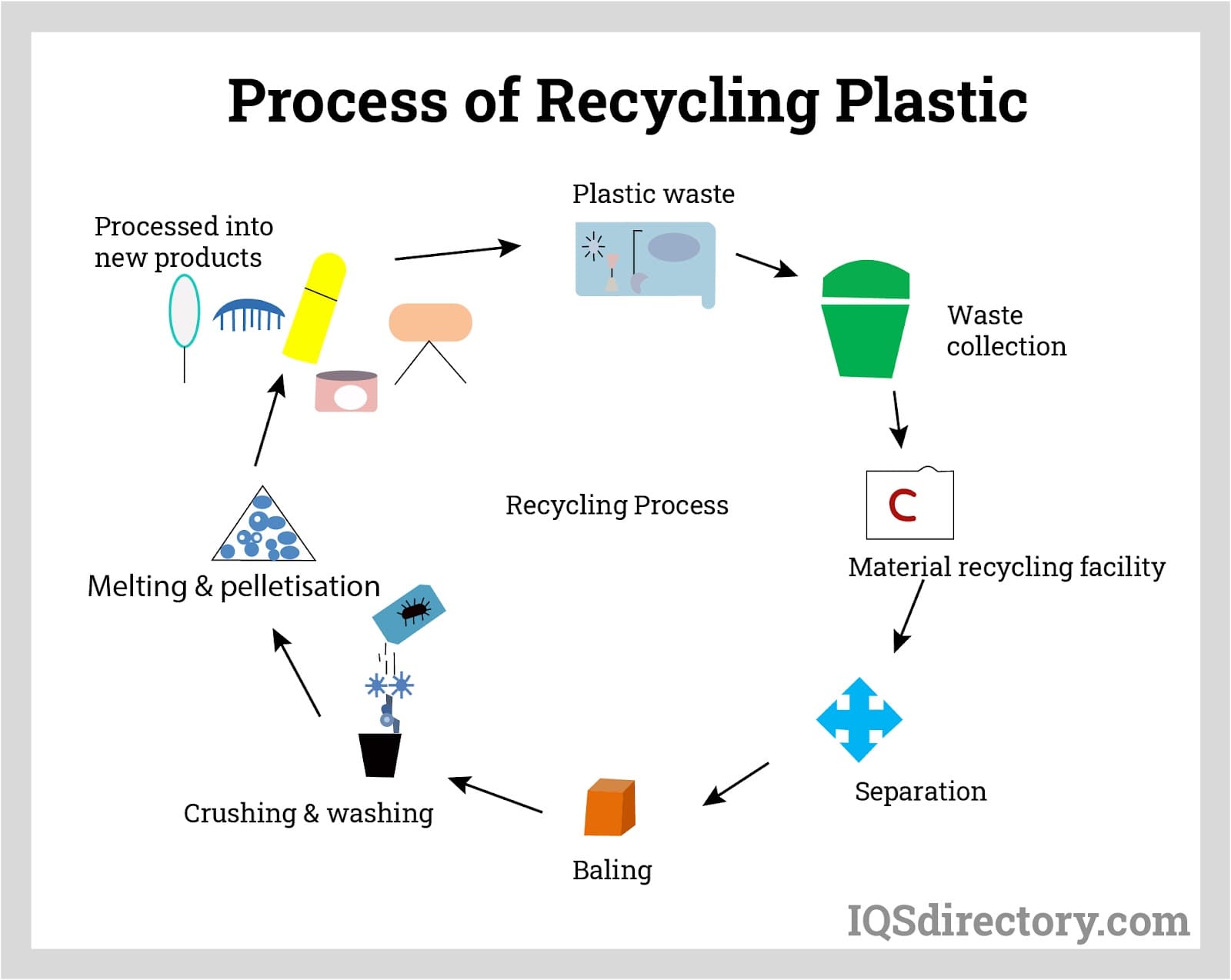

How are plastic bottles recycled? How It Works

Building a Preform. An extruder melts the PET and regrind mix at temperatures of about 500 degrees Fahrenheit. A screw inside the extruder compresses the PET mix and injects the nearly molten material into molds. The mold produces a bottle preform, which is sometimes called a parison. The preform looks like a thick-walled test tube, often.

Plastic Bottle Manufacturing Process Flow Chart Best Picture Of Chart

There are three main types of blow molding methods used in bottle production: 1. Extrusion Blow Molding. In this process, we place the parison inside a mold, and then we use compressed air to blow into the parison, causing it to expand and conform to the shape of the mold. 2. Injection Blow Molding.

How To Reuse Of Plastic Bottles In Construction Engineering Discoveries

Key Takeaways. Plastic water bottles are made from petroleum or natural gas through a process of melting and molding polymer resin pellets into preforms, which are then blown into their final shape using high-pressure air. The production of plastic water bottles has a significant environmental impact, with 500 billion bottles produced per year.

How to Make a Trash Can from Plastic Bottles 6 Steps

Plastic bottles - including water bottles and those used in pharmaceutical packaging - are typically produced using a technique called stretch blow moulding. This process sees plastic pellets heated until they become liquid, then poured into long, thin tube moulds. These plastic tubes then need to be transformed into the required bottle.

How To Make Huge Water Rockets by Splicing Bottles Together! YouTube

1. This YouTube video provides an in-depth look at the manufacturing process of plastic bottles, showcasing how plastic is made from start to finish. Viewers.

When Was The First Plastic Water Bottle Invented Best Pictures and Decription

Water can be coursed through pipes surrounding the mold, which indirectly cools the mold and plastic. Direct methods include using pressurized air or carbon dioxide directly on the mold and plastic. Once the bottle (or, in continuous manufacturing, bottles) has cooled and set, it is ready to be removed from the mold.

Plastic Bottles Types, Manufacturing, Uses, and Benefits

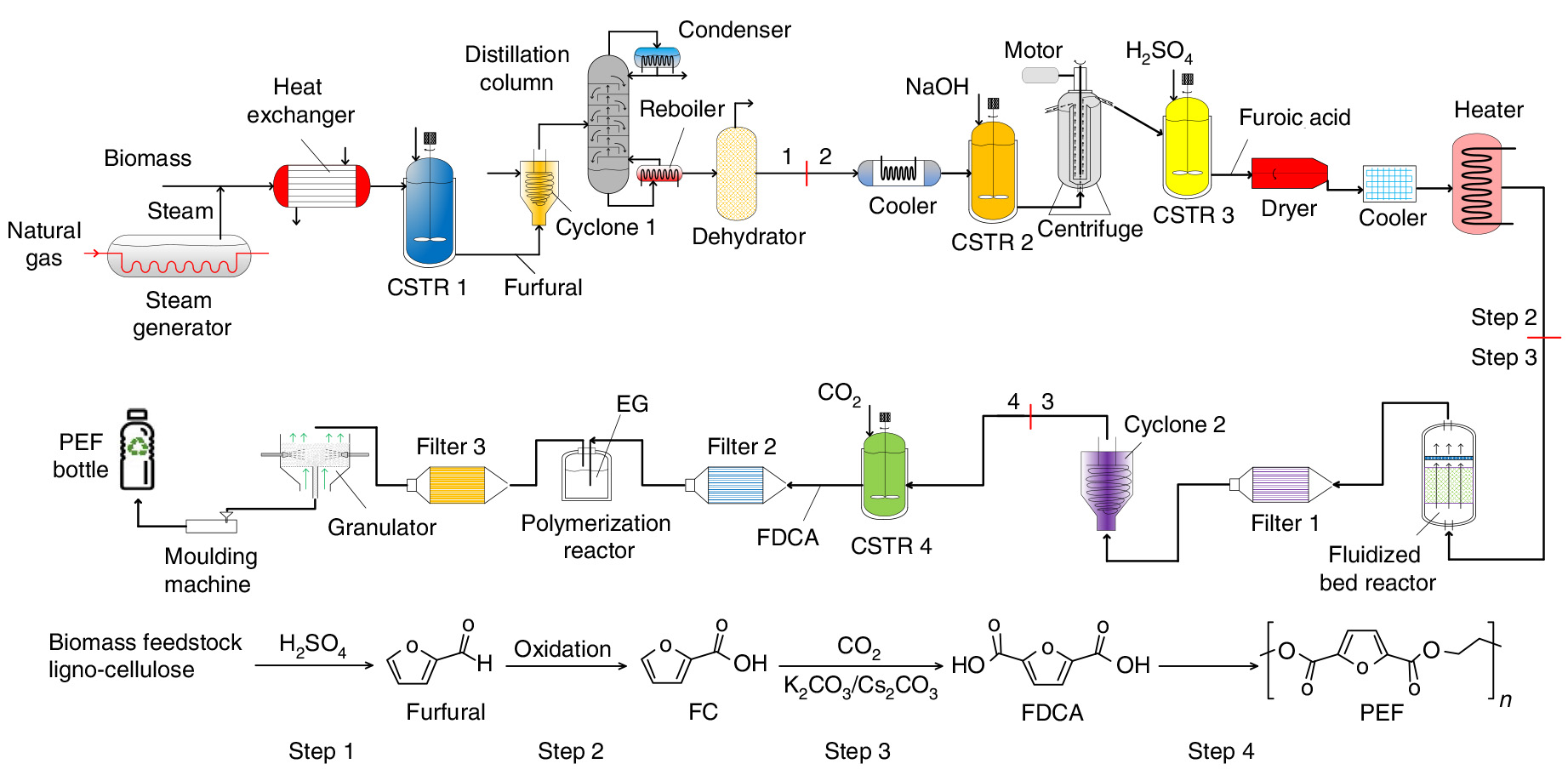

The Coca‑Cola Company's sustainable packaging journey crosses a major milestone this week with the unveiling of its first-ever beverage bottle made from 100% plant-based plastic, excluding the cap and label, that has been made using technologies that are ready for commercial scale. The prototype bottle comes more than a decade after the.

How to Build a House Made From PET Plastic Bottles Owlcation

We need to find ways to reduce our reliance on single-use plastics and find more sustainable ways to package our products." —Dr. David Suzuki. . In the history of plastic, the invention of the plastic bottle in 1947 by DuPont's Nathaniel Wyeth stands as a pivotal moment—marking a transformative shift from traditional glass to the.

- There Can Be Miracles When You Believe

- Little Miss Muffet Nursery Rhyme Words

- St George Sutherland Shire Anglers Club

- Worst Suburbs In Sydney List

- Silk Expert Pro 3 Ipl Long Term Hair Removal Device

- Accommodation Wickham Terrace Spring Hill

- Ddr5 Dual Channel Vs Quad Channel

- The Lake House James Patterson Series

- Australia Square 264 George St Sydney Nsw 2000

- How To Speed Up A Video Snapchat